Research and Development for Bearings

State-of-the-art

Research and development at US Synthetic Bearings

The performance of our bearings are the result of extensive Research and Development (R&D) conducted by US Synthetic engineering teams. Our research staff consists of professionals with advanced degrees in engineering, chemistry, and materials design. With more 40 years of diamond-engineering experience, US Synthetic has worked hard to deliver advanced PCD material and new and better ways of building custom bearings and components for our customers.

US Synthetic Bearings understands that meeting every customer’s exact needs is crucial to a successful product. Because of the drive to meet customers’ every need, USS Bearings is fully dedicated to developing a close working relationship with each customer — providing ongoing research and development designed to find the best solution possible. To ensure product quality is met, the engineering teams do extensive, rigorous testing in our in-house bearing testing facility. This ensures that the best products are developed for customers through extensive testing and evaluation.

Laboratory tests conducted by US Synthetic Bearings have validated the numerous advantages of PCD bearings:

- Low friction coefficients, even with full diamond-to-diamond contact

- Ability to operate in boundary, mixed-mode and hydrodynamic regimes

- Resistance to damage during starting and stopping (when operating in mixed-film or hydrodynamic regimes)

- Ultra-long life

- High load capacities

Deep diamond understanding and experience

Accomplished scientists with more than 50 years of combined diamond research experience lead the US Synthetic research and development efforts. A separate team of application engineers works directly with customers to develop custom diamond solutions that make the best possible use of the latest technology. These engineers have years of experience with PDC design and working with bit companies. A staff of experienced technicians constantly evaluates and tests new products in the laboratory, so the product is tested and ready for application in the field.

All of these experienced professionals work in state-of-the-art research and testing facilities. This includes a full metallurgical lab, an advanced computer-aided design center, and a sophisticated testing lab. These facilities allow our scientists and engineers to:

- Create and optimize new cutter designs using the latest solid modeling software.

- Model and analyze the thermal and mechanical performance of PDC cutters under simulated drilling conditions using finite element analysis tools.

- Quickly build prototype cutters in a dedicated R&D environment.

- Evaluate cutters using scanning acoustic microscopy (C-SAM), optical and scanning electron microscopy, and metallurgical analysis.

- Monitor and improve cutter performance with abrasion, impact resistance, and vertical turret lathe (VTL) testing.

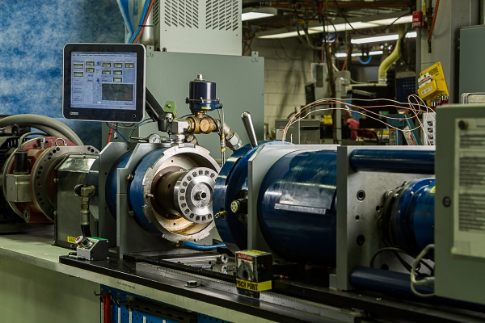

Bearing test machine

US Synthetic Bearings has recently commissioned a new high capacity bearing test machine. This new machine is capable of several types of tests including wear tests (that last up to several months), capacity tests, friction tests, and fluid film tests. The results from these tests are used to improve the bearing products offered to all customers for their specific applications.

Wear testing

During wear testing, a high axial load is applied for extended periods of time — from hours to even months. The total diamond wear in the bearing is then measured and converted to a wear rate. Test results are then used to compare the relative wear resistance of different diamond blends, bearing insert geometries, and bearing insert configurations. The results of these wear tests help the US Synthetic Bearings engineering team design the best bearing possible for a given application. Wear test results are also used to predict bearing life in specific applications. The following are examples of wear test results:

Capacity testing

During performance testing, US Synthetic’s bearings are tested under constant speed, gradually increasing load until bearing failure occurs. Test parameters and bearing designs can be adjusted to meet the customer’s design, speed, load, and cooling flow rate. The data gathered during this testing is used to generate pressure/velocity (PV) failure curves which define the safe operating envelope for a given bearing. Test results can also be used to predict required cooling flow rate, expected heat generation, and frictional loss in customer applications.

Fluid film and friction tests

During friction testing, a constant axial load for the duration of the test, gradually increasing speed until the test is complete, is applied to all tests. Test parameters and bearing design can be adjusted to meet every customer’s design, load, and cooling flow rate requirements. The data gathered from these tests is used to generate Stribeck curves, which define the lubrication regimes (boundary, mixed film, and hydrodynamic) present at various speeds. This helps the engineering team at USS Bearings understand and predict the expected friction coefficients associated with the bearings for each given application.

Prototype Machine Shop

US Synthetic Bearings is committed to fast turnaround times on new bearing designs and bearing test results. For this reason, USS Bearings utilizes a skilled prototype machine shop dedicated to making new bearings quickly and at the highest level of quality. This enables costumers make decisions quickly and with confidence.

Analyses

In addition to laboratory testing, US Synthetic Bearings engineering staff uses finite element models and proprietary bearing design tools to help predict field performance.

High-pressure high-temperature technology

Diamond sintering requires the application of extreme heat and pressure. Typically, diamond is sintered at a temperature of around 1400°C (2550°F). At room pressure, these extreme temperatures would cause the diamond to revert to graphite. Maintaining extremely high pressure during the sintering process allows the diamond to remain in its natural form (see figure). This typically requires pressures of around 60 kbar (nearly 1,000,000 psi)—the equivalent of a 240 km (160 mile) high column of granite.

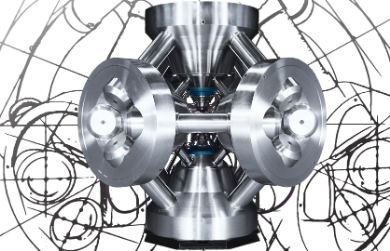

To achieve these extremely high temperatures and pressures simultaneously, US Synthetic uses proprietary cubic press technology. The cubic press consists of six large pistons, each of which is capable of supplying several thousand tons of force. Each piston pushes on a small tungsten carbide anvil, which in turn compresses a cubic pressure cell that contains the raw materials (carbide and diamond crystals). As soon as the cubic press reaches the desired pressure, electric current flows through a resistance heater embedded in the pressure cell to generate the required high temperatures. These conditions are maintained long enough to ensure complete diamond-to-diamond bonding of the individual crystals.

PDC drilling applications

PDCs were first introduced decades ago as a replacement for natural diamonds. These early cutters lacked toughness, were generally limited to the softest drilling applications, and required very specialized bit designs and carefully controlled drilling parameters. Over the years, aggressive innovation and improvements to the process have steadily increased the durability, impact resistance and abrasion resistance of PDCs.

Today’s PDCs are effective in shale, limestone, and sandstone formations. Over time, the PDC-drillable zone will continue to grow and expand (see figure). For example, US Synthetic frequently cuts crystalline rocks for extended periods in a laboratory environment—and is working hard to extend these capabilities to an operating environment.

Today, PDC enhanced bits provide the fastest, most durable and most cost-effective drilling.

Diamond Technologies Education

Our History

ChampionX has been serving customers for over a century. See our vast company history that dates back to the 1800’s.

Our Solutions

Discover all that ChampionX has to offer with our visual interactive tool.

Resource Library

Filter through our latest product literature to find case histories, product brochures, news, and more.

Why work with us

7,300+

Employees

60+

Countries

40+

Manufacturing Locations

400+

Scientists and Technologists