Valves, Controls & Automation

About Norriseal-Wellmark

Norriseal-Wellmark has been a leading supplier of valve and control solutions for more than six decades. From the beginning, we have fostered a culture focused on excellent customer service, invested in our people and our technologies, and created a business rooted in continuous improvement. In short, we’re an organization driven to help you be your best.

Valves

Norriseal-Wellmark offers a wide variety of valves and control solutions used across a variety of high service industries and critical applications across the globe. Norriseal Wellmark’s team of experts is here to help you with your flow control designs and meet your application specifications.

Products and Services

Learn More

Regulators

Wellmark Back Pressure Regulators offer an economical solution for automatic relief of pressure in liquid service.

Products and Services

Learn More

Level Control Switches

Norriseal-Wellmark offers a variety of robust pneumatic and electric liquid level switches for reliable control of oil and gas production equipment such as gas compressor scrubbers, separators, vessels, and safety systems.

Products and Services

Learn More

Valve Positioners and Accessories

Norriseal-Wellmark offers a variety of accessories including site glasses, gauge valves, in-line check valves, meter leveling saddles, and many others for use in flow control applications.

Products and Services

Learn More360° Support

360-degree support

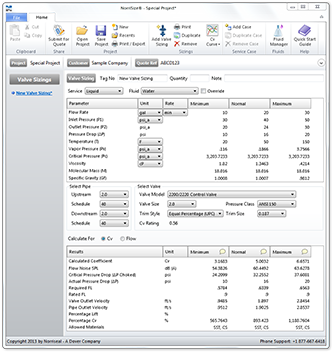

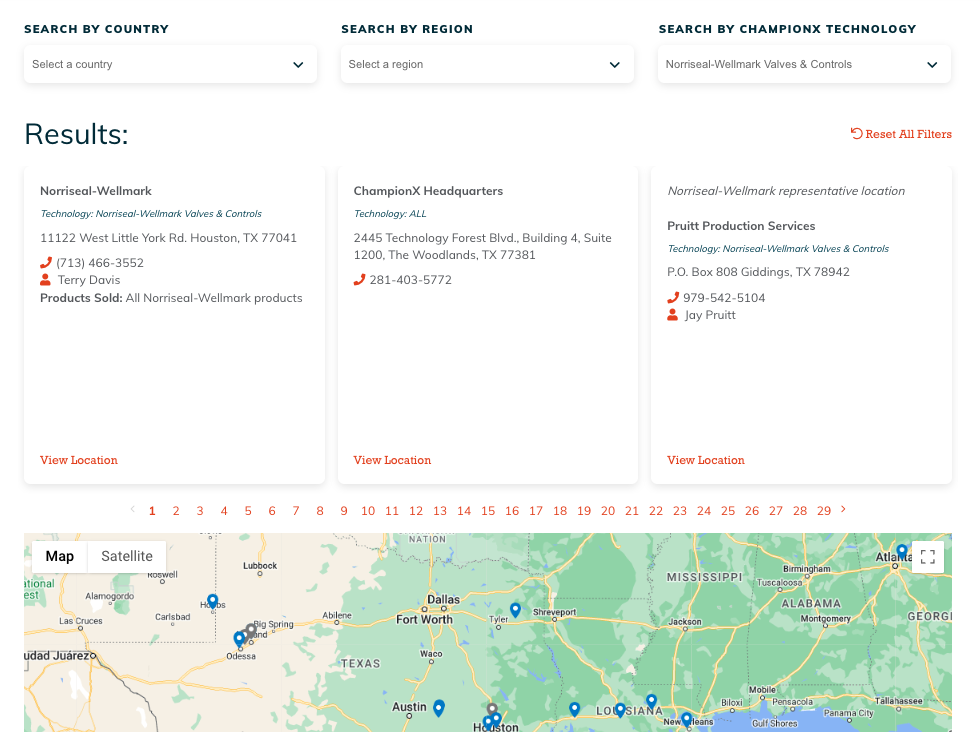

From product selection to problem-solving, Norriseal-Wellmark offers comprehensive support services designed to help you maximize productivity, minimize costs and assure long, trouble-free service for every valve and control product.

Norriseal-Wellmark has in-house engineering, experienced technical support teams and a wealth of information to help you determine proper specifications and optimize every application.

Applications

Upstream oil & gas

Segments

- Wellhead & separators

- Dehydrators & treaters

Applications

- Separation & storage level indication

- Valve position monitoring & automation

- Back pressure valve on separators

Midstream oil & gas

Segments

- Compression & gas plants

- Pipeline & transmission

Applications

- Gas compression

- Recycle valve on compressors

- Dump valve on scrubbers

Marine

Segments

- Shipbuilding

- Propulsion

Applications

- Engine cooling systems

- Cooling piping systems for steam, lubricant & oil

Industrial

Segments

- Industrial process equipment

- Refrigeration

- Construction

Applications

- Cooling of air conditioning & refrigeration condensers

- De-icing sprayers

- Agricultural sprayers

- Cement & additives

Maximize your assets

ChampionX global education and training

Our education and training resources are available to help you gain insight into our market-shaping solutions across artificial lift, oilfield chemical, drilling, and digital technologies. From free virtual webinars to our established ChampionX Production Academy, learn from our industry experts to get the most out of your assets.

Our History

ChampionX has been serving customers for over a century. See our vast company history that dates back to the 1800’s.

Our Solutions

Discover all that ChampionX has to offer with our visual interactive tool.

Resource Library

Filter through our latest product literature to find case histories, product brochures, news, and more.

Why work with us

7,300+

Employees

60+

Countries

40+

Manufacturing Locations

400+

Scientists and Technologists