Never Change Out Another Nozzle

Worry-free 3D printing

Professional 3D-printing companies and 3D-printing enthusiasts understand the benefits of cost, quality, speed, and flexibility when printing actual parts. Unfortunately, the development of embedded filaments (carbon fiber, glass, metals) is creating an even bigger need for more abrasion-resistant nozzles. To address this limitation and others of brass, professional 3D-printing companies and 3D-printing enthusiasts are considering specialty nozzles made of steel, tungsten carbide, ruby, and now diamond.

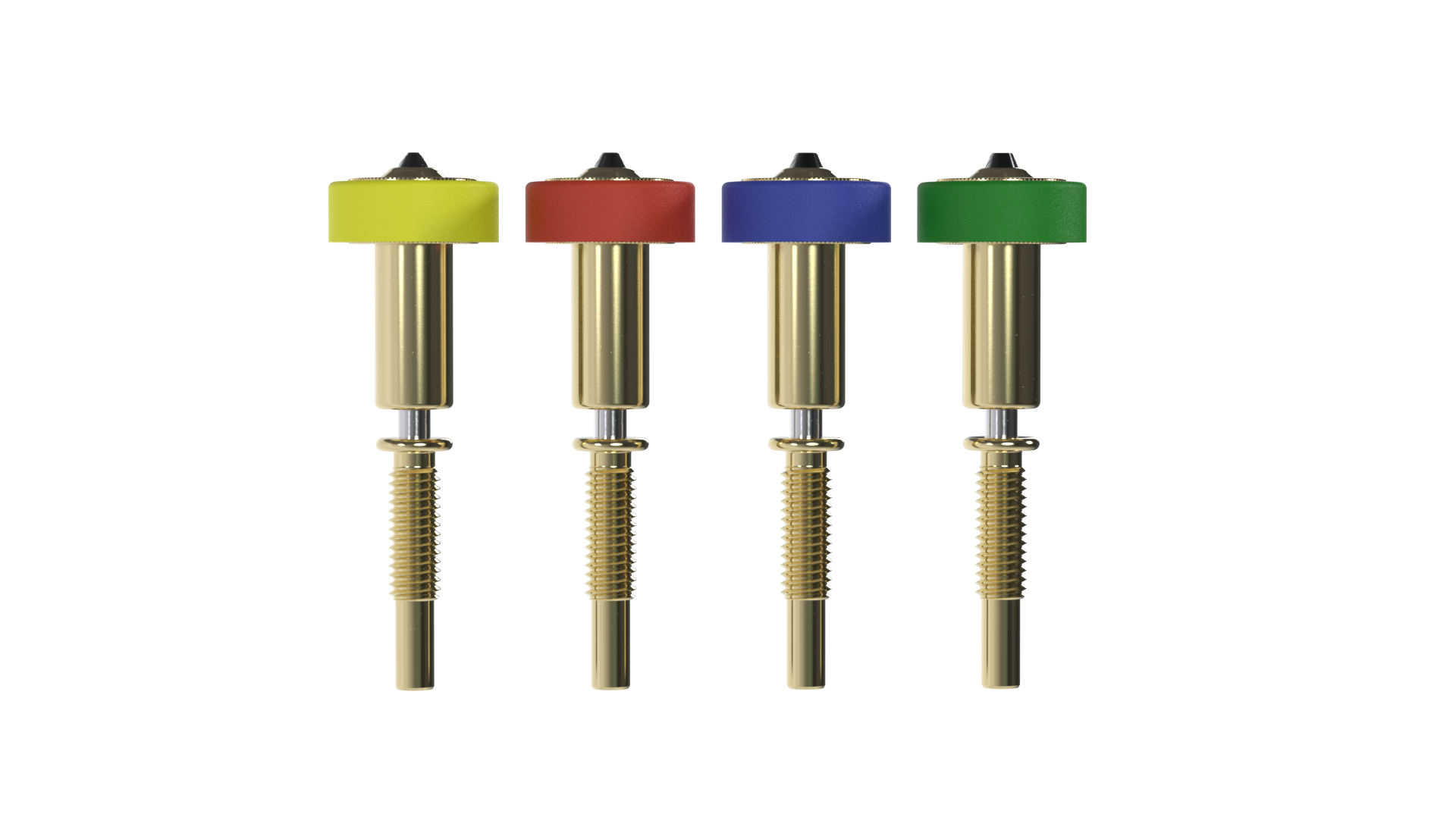

Of the options available, the clear leader in worry-free printing are DiamondBack™ Nozzles — delivering unmatched wear-resistance and versatility.

Precision Print | Any Filament | Longer Life

The DiamondBack Nozzle:

- Prints any filament–no nozzle change out required

- Improves layer adhesion and quality

- Has a solid diamond tip, NOT a diamond coating

- Is easier to clean and reduces tip clogging

- Delivers unmatched wear resistance

- Lowers required operating temperature

- Improves extrusion efficiency

- Is made in the USA

Testimonials

Be the First to Experience

The diamond difference

With more than 40 years of diamond-engineering experience, US Synthetic has worked hard to deliver advanced Polycrystalline Diamond (PCD) material for durable 3D Printer Nozzles. Our diamond sintering process requires extreme heat and pressure. Typically, diamond is sintered at a temperature of around 1400°C (2550°F).

Maintaining extremely high pressure during the sintering process allows the diamond to remain in its natural form. This typically requires pressures of around 60 kbar (nearly 1,000,000 psi). To achieve these extremely high temperatures and pressures simultaneously, US Synthetic uses proprietary cubic press technology. As soon as the press reaches the desired pressure, electric current flows through a resistance heater embedded in the pressure cell to generate the required high temperatures. These conditions are maintained long enough to ensure complete diamond-to-diamond bonding of the individual crystals.

Our History

ChampionX has been serving customers for over a century. See our vast company history that dates back to the 1800’s.

Our Solutions

Discover all that ChampionX has to offer with our visual interactive tool.

Resource Library

Filter through our latest product literature to find case histories, product brochures, news, and more.

Why work with us

7,300+

Employees

60+

Countries

40+

Manufacturing Locations

400+

Scientists and Technologists