Upstream Flow Assurance

Find answers to upstream flow assurance problems no one has seen before – much less solved. Whether deposit control, pour point depression, or a cold restart of a pipeline challenges your operations, ChampionX develops industry-leading chemical flow assurance solutions that deliver flow assurance for topside and umbilical applications alike. Our chemical flow assurance services increase our customers’ profitability, from high temperature-high pressure applications offshore to unconventional shale production and massive wet gas production trains onshore.

Flow Assurance Solutions

Asphaltene Management

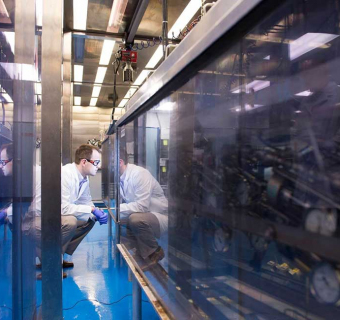

Asphaltenic compounds that have destabilized can damage formation, plug production and transport equipment, and destroy profits. These compounds are found in most liquid oil and gas streams. Managing such compounds can be complex due to differences in produced oil and system operating conditions. ChampionX takes a holistic approach to asphaltene management, recreating your unique circumstance in a lab environment. This allows us to create and supply cost-effective chemical treating methods perfectly suited for your environment, leading to increased profitability of your operation.

Not only can effective and optimized asphaltene management improve profitability, it can also:

- Maximize your production potential by preventing asphaltene deposits that can cause restrictions in your equipment

- Preserve asset integrity

- Minimize downtime

Hydrate Management

Hydrates can lead to safety hazards and production losses whether in deep water, mega gas trains, or onshore gas transmission lines. The ChampionX low dose hydrate inhibitor (LDHI) portfolio includes anti-agglomerates (AA) and kinetic hydrate inhibitors (KHI) that have been proven in various environments. With our industry-leading research team and testing capabilities, we assess your problems and develop customized hydrate mitigation plans for the lifecycle of your assets.

Hydrate Formation Modeling

With the ChampionX hydrate formation modeling program, we’re able to predict future hydrate formation in a particular system, while designing and implementing hydrate management systems perfectly suited for your environment. This predictive modeling can prevent unexpected production interruption or increased operating expenses you may face otherwise.

Offshore Production Hydrate Management

The management of hydrates in offshore production can be difficult due to higher produced water cuts that complicate any effective inhibition of hydrate formation. ChampionX has developed cost-effective hydrate inhibiting solutions developed specifically for offshore users providing a greatly reduced impact on produced water quality.

Paraffin Management

Paraffins, also known as wax, are saturated hydrocarbon fractions naturally found in crude oil. In the production process, crude oil cools as it flows from the reservoir to the surface, sometimes leading to wax crystallization. This crystallization can, in turn, lead to wax deposition and build up that makes it difficult for oil to flow uniformly through a pipeline.

Challenges from paraffinic crude effect every aspect of the hydrocarbon value chain whether it’s production loss to transportation. ChampionX prevents and remediates paraffin wax deposits using tailored products and field service to restore production capacity and enhance your bottom line. Both our laboratory and field testing facilities ensure a paraffin management program is selected that will best suit your needs.

Some of the benefits of Paraffin Management include:

- Increased production/restored production capacity

- Improved operating efficiencies

- Reduced OPEX

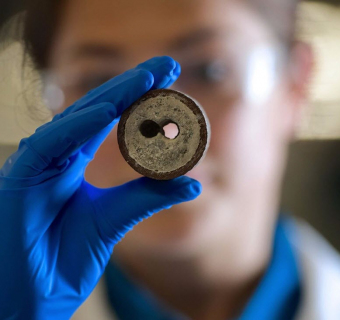

Scale Management

Mineral scale deposition can be a major issue when it comes to flow assurance. When it comes to the oilfield, there are two most common types of scale: calcium carbonate and barium sulfate. Calcium carbonate forms largely due to depressurization, while barium sulfate is created when there is incompatibility between formation fluids and the injection water. Although these are the most common, there are many types of scale that can cause flow assurance issues and impact performance.

ChampionX scale inhibitor treatments range from squeeze treatment deep in the reservoir to deep water umbilicals and topside pipeline applications. With our total scale management programs, we offer predictive modeling, advanced design and application techniques, coupled with process monitoring. All of which is coordinated by the world’s leading subject matter experts.

Wellbore Cleanout

Wellbore cleanouts can be costly and are often necessary to recover optimum production during the lifecycle of a well. Over time, debris builds up, leading to flow restriction and reduced production. Mechanical cleaning comes at a significant cost to operators and drilling a new well requires capital. Additionally, providers who offer a chemical solution to clean out the wellbore may lack the expertise to test, design, and deliver a suit of chemistries in a safe and effective manner.

ChampionX provides a comprehensive customized well treatment plan with a unique sequencing of varying chemistries to remove buildup caused by iron sulfide, H2S, mineral scaling, bacteria, paraffin, and/or asphaltene followed by weekly monitoring and evaluation against success criteria. The RenewIQ Wellbore Cleanout program combined with our experience has been repeatedly proven to increase well production at a higher return on investment than drilling a new well or other cleanout methods.

Our History

ChampionX has been serving customers for over a century. See our vast company history that dates back to the 1800’s.

Our Solutions

Discover all that ChampionX has to offer with our visual interactive tool.

Resource Library

Filter through our latest product literature to find case histories, product brochures, news, and more.

Why work with us

7,300+

Employees

60+

Countries

40+

Manufacturing Locations

400+

Scientists and Technologists